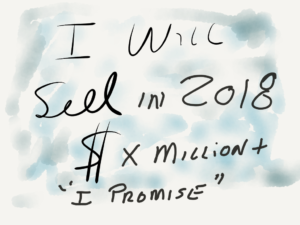

After much reading, discussing and watching I am convinced that over 95% of people going into a new year don’t have written measurable goals for the year. Many or probably most have heard this and know the importance of goal setting goals, still not written down.

If you are a sales person and say “Wow! I need more sales to make my year!” — You may be out of luck. If your sales cycle takes longer than 10 weeks from start to close to shipment, you are running out of time.

Now is the time to begin looking toward the New Year 2019. Begin by setting an appointment with yourself for 30 – 60 minutes. Get blank paper or a blank computer screen and begin writing your thoughts and ideas for accomplishment next year. This first cut at goal setting doesn’t have to be neat — just take time to think about and write your ideas and thoughts down. My beginning session is usually quite messy and unorganized.

Put this information away in a place you absolutely won’t forget where it is so that you can retrieve it, early December. Then set an appointment with yourself for 30 – 60 minutes early December and get your list out.

In December you will be amazed at the progress you will have already made toward thinking about and planning your goals for next year. Your fist list may be messy, but you will be ready to define and refine the list. You will be subtracting, adding and modifying the original set of goals. Make the list a little neater and resolve to begin your goals and measure your goals.

Why do I believe in doing this? It’s because I use this method every year and then I set a tracking system and measure progress. This works!

Try for yourself and get into the 5% group of people who actually write and strive to achieve their goals. Remember a lot of “Luck” goes along with a lot of preparation.

While continuing to build my own goal system I have found and in process of reviewing a software program that looks very promising — Click and have a look

I’ll comment further as I look at this software — Let me know your thoughts.

Make 2019 your best year yet!